Stacking from a cast surface to a machined feature Its easy to get confused about how to stack from a cast surface to a machined feature. Typically only one part is detailed in each drawing.

Main Factors When Design Drawing For Investment Casting

While in the molten or liquid state it is poured into a mold or vessel to create a desired shape.

. Structural steel and sheet metal are the usual starting materials for fabrication along with the welding wire flux and. We create higher assembly part numbers from our castings usually changing the. I think it is appropriate to use tertiary at MMC but I do not want to add the cast hole size and tolerance to the machining drawing unless I cant avoid this.

All your different designs will be documented at the same time in the same part file and the drawings fall out from here if you need to define that casting as its own controlled drawing. Figure G4 Part 7 Casting File We select the Inventor icon in the upper left corner of the Inventor 2012 window and we select Save As from the drop down menu. In some eras and in some industries the foundry was given the drawing of the finished part and they create a drawing of what the finished casting should look like and of course the pattern needed to create the cast part.

The machine drawing can call out cast surfaces if they are not machined. It requires the metal to be heated at a temperature truing it to liquid form and then poured into molds prepared in the shape of the desired product. Assembling joining of the pieces is done by welding binding with adhesives riveting threaded fasteners or even yet more bending in the form of a crimped seam.

Consider the figure below. Difference between casting vs forging. I agree having separate drawings for casting and machining parts.

To summarize machining is ideally used for prototyping small quantity runs precision tolerances and components with large complex volumes. Specific Casting ProcessesMost casting. One reason is if the machined part changes the casting drawing may change.

Forging is the application of thermal and mechanical energy to steel billets or ingots to cause the material to change shape while in a solid state. Figure G5 Part 7 Machining We then can close the Part7 drawing and open the. This technical drawing shows the machine parts assembly using joining by threaded fasteners.

Depending on the needs of the customer Decco also provides machined andor painted castings. The casting drawing should not indicate machining data. Tmoose Mechanical 27 Jan 12 1245.

It is presented through a number of orthographic views so that the size and shape of the component is fully understood. The cast to machine workflow works great for Inventor but is backwards to the normal design workflow. Part drawings and assembly drawings belong to this classification.

This tnternational Standard applies both to general tolerances andor required machining allowances given on a. It was not necessary to machine the gear teeth. Machining sensitiviy analysis for both options change in total income had the most effect 20 change in income resulted in 30 change in present value highlow for casting electricity was significant as well larger amount higher significance salvage least signigficant sensitivity analysis conclusion we chose the machining process equipment cost.

The machined datums are also located to the cast datums. Casting is the process where metal is heated until molten. To the dimensions of cast metals and their alloys produced by various casting manufacturing processes but see also Introduction g and clause 51.

Machining details are generally used when machining a rough part into a finished part. We name the file Part 7 machining and push the Save button. Datum casting vs machining joebk Mechanical OP 16 Oct 07 2112.

In the casting sketch both the casting and the machining. When it comes to manufacturing metal parts and components there are often multiple ways to achieve the same end result. Machining is necessary the machining expense is reduced by casting close to final shape.

There are two types of machine drawing. Much of the machine work is done in house with our Atrump CNC milling machine and our Clark lathe. Cast molding is great for large quantity runs exactness from lot to lot and parts where a skin or detailed texture is important.

Tertiary datum used to position some machined features is a cast hole. Subsequent machined features such as the threaded hole are located. We see our casting drawing and we will save the file as Part 7 machining.

If the part is cast at another company they dont care about the machined data. Another example of a cast tooth gear is the pinion gear produced from cast high-manganese Hadfield steel for an electric mining shovel shown in Fig. A machining detail drawing provides all the information needed to manufacture a specific part and is used to machine the casting into a finished component.

A method around this dilemma is to start them both at the same time. Sand casting is great for small-lead time projects as the molds can be typically made within a day if. Each has its own unique capabilities and pros and cons.

Turn any sketches with machining geometry on then derive the machined version. Classifications of Drawings 41 Machine Drawing It is pertaining to machine parts or components. Ideal Applications for Machining and Molding.

Machining Drilling 008 -003mm Milling 008mm Turning 005mm Abrasive processes Grinding 0008mm Lapping 0005mm Surface finish roughness Casting Die Casting Good 1-2µm Investment Good 15-3 Sand Casting Poor 12-25 Metal forming Cold rolling Good 1-3 Hot rolling Poor 12-25 Machining. Casting extrusion and forging to name a few are all reliable methods of producing metal products. Delete Face is another way that you can remove some geometry.

Die casting naturally will need more prep as it requires mold machining testing and other set-up steps related to the die casting process. Not all the castings we make are purchased as a raw casting. Is required to remove excess material from the forged or cast component and give it.

I am working on the design of a machined casting. You have the geometry for that as well as any of the final machine pieces that you need to show. A machining detail drawing will specify the.

The cast surfaces are located to the cast datums XYZ.

Solved Prepare Both The Casting And The Machining Drawings For The 1 Answer Transtutors

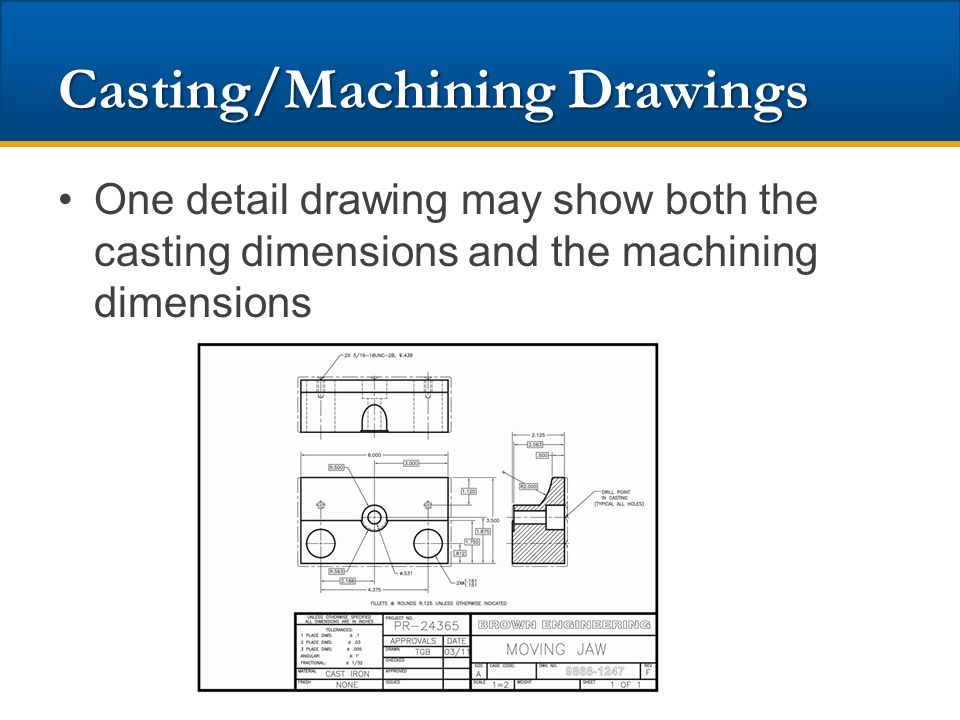

15 Detail Drawings Permission Granted To Reproduce For Educational Use Only Explain Terms And Standards Related To Various Types Of Drawings Used In Ppt Download

Quick Answer Can A Machining Drawing And A Casting Drawing Be Combined Seniorcare2share

Module 3 Unit 15 Detail Drawings Ppt Video Online Download

0 komentar

Posting Komentar